Science of ducting air

Following on from the diverging/converging duct diagram on the prior page, clearly for a vehicle, the aft converging section is less practical since the engine sits behind the radiator. The converging section in an airplane duct is design to accelerate the air as it exits the duct to reduce the drag. We don’t care so much about aerodynamic drag in a Range Rover! So we’ll focus on the front diverging section. As the photos at left show, here are examples of diverging inlet ducts on a racing car radiator. They follow the same design principle - give the inlet air a greater volume inside the duct which slows it down. The static pressure increases while the dynamic pressure decreases.

As this slower air passes through the radiator, it spends more time in contact with the radiator tubes and absorbs more heat as it does so.

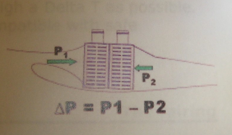

The diagram at left shows an important concept. For there to to a flow across a radiator, there must be a pressure difference, a “delta P” across it. In the this diagram, the delta P is = P1 - P2. Clearly P2 must be lower than P1 and in our case, we achieve that by a fan, or fans, pulling air through the radiator. In practice, the fans create a low pressure area behind the radiator, and with this low P2, we have our delta P.

So having chopped up the Classic bodywork and added the two oil coolers, we must now go back and construct divergent ducting in front of both oil coolers, and to the degree we can do it, in front of the radiator, to slow down the airflow before it reaches these 3 units.

Using a coolant other than 50/50 glycol/water (“antifreeze”):

It can be shown that the thermal conductivity of water is 50% better than a 50/50 glycol/water mix. This is because of the surface “wetting” ability of water versus antifreeze. Swopping to water is easy but it is important to use the right type. Tap water contains dissolved salts as does distilled water so these are not recommended because these salts will gradually build as deposits in the water ways. De-ionized water is not recommended becuase it will react chemically with the aluminum surfaces in the engine. The best choice is water that has been purified by reverse-osmosis; this is frequently found in supermarkets labelled as “drinking water”. To this water, it is critical to add a corrosion inhibitor like No-Rosion or HyperKuhl from Applied Chemical. This coats the aluminum surfaces and protects them from deposits and corrosion. Alternatively use “Water Wetter” from Red Line Oils - this does essentially the same thing.